Organizing Processes by Value Stream and Towards High Productivity

Businesses are always on the lookout for ways to improve operations and management, whether in manufacturing or non-manufacturing environments. Welcome to LEAN strategies, a systematic way of examining any process to streamline and eliminate excess work and ensure best practices are being used whenever possible, both at work and in the home.

A graduate from the BCIT’s Business Operations Management program and well versed in Six Sigma methodologies, Bonnie Wall has been an integral part of the LEAN management implementation at Imprint Plus™. As the Operations Manager, she’s leveraged LEAN thinking and enacted LEAN processes to oversee the manufacturing and distribution of the company’s products.

Imprint Plus™ is the leading supplier of reusable name badges and signage systems to over 35,000 customers in 74 countries around the world.

Hello Bonnie, thank you for offering your time to allow me to interview you. Could you tell us how LEAN thinking matches your expectation in terms of management methods?

Lean management is about focusing on what the customer values and continually reducing waste and interruptions. This matches my expectation in terms of management methods because interruptions, unclear instructions, and standards can lead to employee frustration and errors in output and quality.

Empowering employees to find waste and eliminate it will streamline their work to increase employee and customer satisfaction. This in turn allows our company to be able to respond quickly to changing customer demand, as well as reducing costs to keep product pricing competitive.

Describe your experience relating to LEAN training.

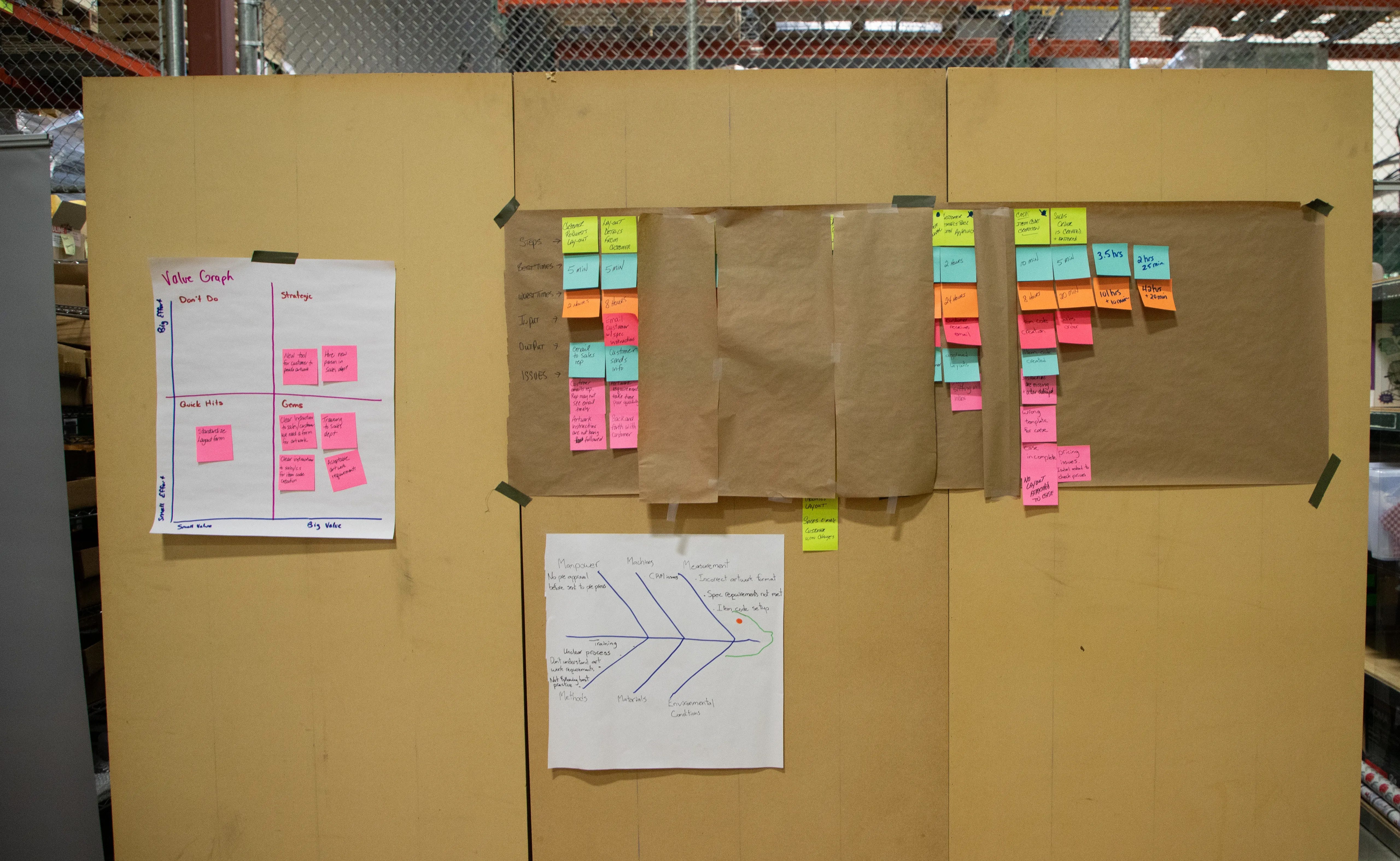

Lean training has changed the way I view work and tasks. I put on my Lean lens and look for what the customer values in what we are doing. Our leadership team empowers our employees to seek out customer value as well. To learn about customer value and viewing work through a Lean lens, we provide in-house Lean training that encompasses learning about the tools to identify waste and remove it from processes. We also showcase how these tools can be used outside of a manufacturing environment and be applied to an office setting.

I also have changed how I conduct my regular life outside work. It helps me save time at home when fulfilling day-to-day activities. For example, mowing the lawn – if you sit down and think about the activity and the steps involved in completing that activity, you are sure to find waste. You may be able to cut down 15 minutes by gathering all your tools at once or moving the grass trimming bins closer to the point of use. Even looking at what area of the lawn you start and finish at. Plus, removing things like excess movement (walking), not only will make the task easier for you, but it will shorten it. The 15 minutes saved can turn into an additional 15 minutes on an activity you enjoy.

Why is LEAN a valuable business tool?

Having a lean company is about continually improving the company processes to make room for growth, increasing employee satisfaction, and reducing process costs. We want to ensure the customer is only paying for what they value. There is a misconception that Lean management is about laying employees off to reduce costs.

‘Lean Is A Way Of Thinking’

What do you think LEAN thinking can bring to organizations? Can it work with all departments

Lean management is not just for manufacturing. Many offices adopt a lean culture and find many different ways to save time navigating through the computer or even improving filing systems.

Your position as an Operations Manager is very challenging. What is your main strategy to achieve efficiency and high productivity?

The key to achieving efficiency and high productivity is to create standards. If standards are defined and written, this reduces confusion and the number of errors an employee can make. Unclear standards are one of the main root causes for rework and employee frustration. Poorly defined goals and objectives also lead to overproduction. Overproduction is a waste of company resources and materials.

Bonnie Wall is the Operations Manager at Imprint Plus™ name badges.

Click here to read “How to Be Lean – Part 2” by Bonnie Wall.

Read more about 8 Steps for Lean Problem Solving.

What are your thoughts on the Lean management system? Has it helped your organization? Follow our Imprint Plus Facebook page and let us know. If you’re interested in reading more on LEAN management, check out our other blogs.

Like Our Posts, Want More? Follow our Facebook and LinkedIn Company Page.

Imprint Plus Canada

Imprint Plus Canada